STRIP

DRYING SYSTEMS

Since

1979, Air Liquid Systems, Inc. has designed and manufactured a broad line of

complete strip drying systems, including

heaters, interconnecting piping, piping supports, and all components for seamless

installation.

APPLICATIONS

•

Cleaning

• Quenching

• Surface Conditioning

• Quenching

• Surface Conditioning

• Tension Leveling

• Chemical Treating

• Pickeling

• Chemical Treating

• Pickeling

ANY

PROCESS WHERE STRIP NEEDS TO BE DRIED

AIR

SUPPLY

Air

Liquid Systems, Inc. supplies all complete strip drying systems with Gardner

Denver’s cast multi-stage centrifugal blowers, complete with

base, coupling, coupling guards, and electric-driven motor. Materials of construction

are cast iron heads and sections, fabricated or cast aluminum impellers mounted

on a ground and polished shaft, and a fabricated steel base. All blowers are

factory run to ensure proper operation with vibration levels less than 0.28

in./sec. (7 mm/ sec.) velocity.

DRY

STRIP GUARANTEED

Below

you will find examples of the strip drying equipment offered by Air Liquid Systems.

Each system supplied by

ALS is guaranteed to provide dry strip. Contact us with any questions.

ALS is guaranteed to provide dry strip. Contact us with any questions.

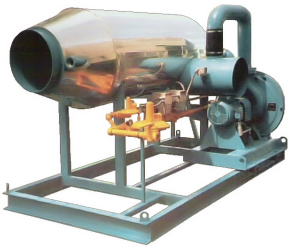

Direct

Fired Gas Heater complete with “IRI” type valve

train, a combustion air blower, and a heater protection control panel. Safety

shut-down features include settings for high gas pressure, low gas pressure,

low combustion air flow, low main air flow, and high temperature. This unit

is designed for a discharge temperature of 300º F-350 º F (149 º

C-177 º C) with the high temperature limit set at 450 º F (232º

C).

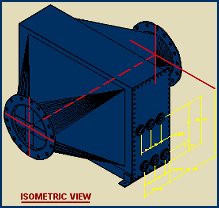

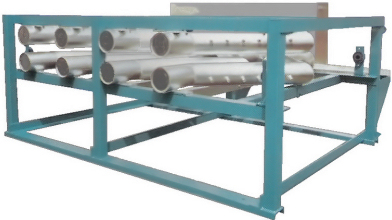

Horizontal

Header Support Table

with sound enclosure. The sound enclosure includes a drip pan and vent fan for removal of hot moist air from the cabinet. Field testing of the noise level of this unit is less than 85 decibels.

Header Support Table

with sound enclosure. The sound enclosure includes a drip pan and vent fan for removal of hot moist air from the cabinet. Field testing of the noise level of this unit is less than 85 decibels.

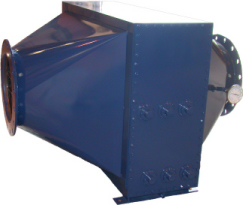

Horizontal

Header Support Table with four (4) sets of 6” (152 mm)

diameter, 30º “V” headers with adjustable slots, entry and

exit EDPM-coated

header protection rolls (not

shown), and air distribution

box. This unit is used to dry

steel strip after cleaning at

968 ft./min. (295 m/min.), 49”

(1245 mm) strip width.

header protection rolls (not

shown), and air distribution

box. This unit is used to dry

steel strip after cleaning at

968 ft./min. (295 m/min.), 49”

(1245 mm) strip width.

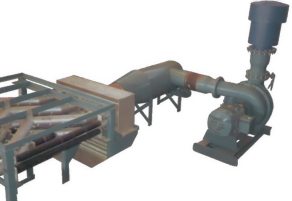

Strip

Drying System with a direct fired gas heater located after chemical

treatment. This system

is designed to dry 49” (1245 mm) wide strip

at line speeds of up to 600 ft./min.

(182 m/min.).

is designed to dry 49” (1245 mm) wide strip

at line speeds of up to 600 ft./min.

(182 m/min.).

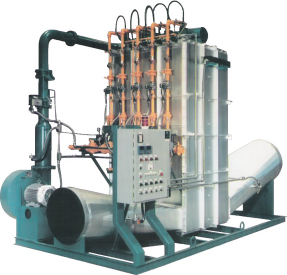

Strip

Drying System with a steam heater on a push-pull pickle line.

This system is designed to dry 72” (1830 mm) wide strip at speeds of up

to 500 ft./min. (152 m/min.).

Vertical

Header Support Structure with three (3) sets

of 6” (152mm) diameter, 15º “V” headers with adjustable

slots, entry and exit EPDM-coated header protection rolls, and air

distribution

box. This unit is used to dry

steel strip after quenching at 600 ft./min. (182 m/min.), 49” (1245mm)

strip width.

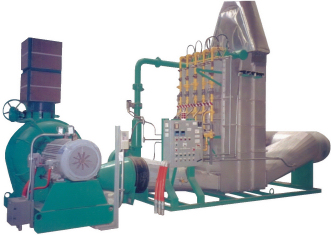

Strip Drying

System with an indirect

fired

gas heater located after chemical treatment. This system is designed to dry

72” (1830 mm) wide strip at line speeds of up to 600 ft./ min. (182 m/

min.).

Indirect

Fired Gas Heater designed with a five (5) burner zone system

which allows for operation of one or more burners, optimizing the units efficiency.

Steam

Fired Heater

33” x 48”, 6-row, red brass.

33” x 48”, 6-row, red brass.

Our

services include total system proposals, design, manufacture, installation supervision,

and start-up support. In addition to complete systems, Air Liquid Systems supplies

all necessary spare parts.

ALS’s Strip Dryers can be provided with steam heaters, direct fired gas heaters, indirect fired gas heaters, electric heaters, or no heat, depending upon conditions and customer preference. Each system is guaranteed to provide completely dry strip.

ALS’s Strip Dryers can be provided with steam heaters, direct fired gas heaters, indirect fired gas heaters, electric heaters, or no heat, depending upon conditions and customer preference. Each system is guaranteed to provide completely dry strip.